Why Engineered Wood Furniture is Increasingly Popular in Hotels

Thứ 2, 15/09/2025

Administrator

93

Hotel interiors demand materials that balance beauty, durability, and cost-effectiveness. In recent years, engineered wood furniture has emerged as one of the most popular solutions in the hospitality sector. Unlike traditional solid wood, engineered wood offers consistent quality, design versatility, and sustainability at a more affordable price point. For hotels that need to furnish dozens or even hundreds of rooms, this material provides the ideal combination of style and practicality. Why is engineered wood now the go-to choice for hoteliers worldwide? Let’s explore together with Ngoc Hoang Anh in the article below.

1. Understanding Engineered Wood in Hospitality

Engineered wood has become one of the most important materials in hotel interiors, offering a practical alternative to traditional solid timber. In hospitality projects where durability, consistency, and cost efficiency are critical, this material provides significant advantages. By combining natural fibers with modern technology, engineered wood delivers both aesthetic appeal and structural reliability, making it a preferred choice for large-scale hotel furniture production.

1.1 Definition and Composition

Engineered wood is produced by breaking down natural timber into fibers, veneers, or thin layers, which are then bonded with resin under heat and pressure. This process creates panels such as plywood, MDF, and particleboard that are uniform in density and appearance. For hotels, this uniformity is a major advantage because it ensures consistent quality across hundreds of rooms and public spaces.

1.2 Key Differences from Solid Wood

Unlike solid wood, which may contain knots, cracks, or inconsistencies, engineered wood is designed for stability and predictability. It resists common problems such as warping and splitting, especially in environments with fluctuating humidity. This reliability allows hotel operators to reduce long-term maintenance while still enjoying the warmth and elegance associated with wooden interiors.

1.3 Versatility in Hospitality Applications

Engineered wood adapts easily to different design concepts, from minimalist urban hotels to luxury resorts. It can be veneered to replicate the look of natural hardwood, laminated for modern finishes, or painted for a clean and contemporary style. This flexibility allows hoteliers and designers to customize interiors according to brand identity while maintaining cost efficiency and durability.

2. Cost Efficiency and Large-Scale Production

Furnishing a hotel often requires hundreds of identical items, from beds and wardrobes to desks and chairs. This scale of investment makes cost control a critical factor for hoteliers. Engineered wood offers a unique balance: it reduces material and production costs while ensuring consistent quality across large volumes. For projects where uniformity, affordability, and timely delivery are essential, engineered wood has become the most practical solution in modern hospitality.

2.1 Lower Production Costs

Compared to natural hardwood, engineered wood is significantly more affordable to produce. The manufacturing process uses smaller fibers and by-products that would otherwise go to waste, reducing reliance on expensive solid timber. Hotels benefit from this efficiency by being able to allocate budget savings to other areas such as décor, technology upgrades, or guest services, without compromising the look and feel of their interiors.

2.2 Scalability for Hotel Projects

Because engineered panels are uniform in density and size, manufacturers can produce furniture in bulk with minimal variation. This scalability is particularly valuable for hotel chains that require identical furniture for multiple properties or brands. Consistent production not only maintains a cohesive design identity but also streamlines logistics, allowing for faster installation and project completion.

2.3 Reliable Supply and Availability

Engineered wood is widely available, with strong supply chains that can meet the demands of large-scale projects. Unlike exotic hardwoods that may face shortages or long lead times, engineered products can be manufactured on demand. This ensures hotels avoid delays in opening schedules and can rely on steady availability when planning future renovations or expansions.

3. Durability and Performance in Hospitality Settings

Hotel furniture is exposed to constant use, from guests moving luggage to staff performing daily cleaning. This high level of wear requires materials that can endure without losing their appearance or function. Engineered wood offers stability, resistance to common damage, and longevity, making it highly suitable for demanding hospitality environments.

3.1 Resistance to Warping and Cracking

Traditional solid wood can warp or crack when exposed to humidity changes, especially in tropical or coastal locations. Engineered wood is manufactured for dimensional stability, reducing these risks significantly. For hotels, this means fewer issues with swollen doors, uneven panels, or split furniture surfaces, ensuring interiors remain reliable over time.

3.2 Protective Finishes for Daily Use

Engineered wood furniture can be enhanced with laminates, veneers, or coatings that add protection against scratches, stains, and moisture. These finishes make cleaning easier for hotel staff and extend the life of the furniture even under heavy use. Guests continue to enjoy furniture that looks new, while hoteliers save on maintenance and replacement costs.

3.3 Longevity Under Heavy Traffic

In spaces like lobbies, restaurants, and conference halls, furniture must withstand constant traffic and repeated handling. Engineered wood offers the durability required for such settings, maintaining its structural integrity even under pressure. This performance makes it a dependable material for hotels seeking long-term value and consistent guest satisfaction.

4. Sustainability and Eco-Friendly Advantages

Sustainability has become a central priority in modern hotel design, with travelers increasingly choosing properties that demonstrate environmental responsibility. Engineered wood aligns with this shift by maximizing resource efficiency and reducing reliance on rare hardwoods. Its eco-friendly production process and compatibility with global green standards make it a practical solution for hotels aiming to balance aesthetics with sustainability.

4.1 Efficient Use of Resources

Engineered wood is made from smaller fibers, veneers, and by-products that would otherwise be discarded. By reusing these materials, manufacturers reduce waste and minimize the need to cut down large trees. For hotels, this translates into a design approach that supports environmental preservation without sacrificing quality or beauty.

4.2 Reduced Environmental Impact

Compared to solid timber, engineered wood has a lower overall impact on forests and biodiversity. Many manufacturers now use water-based adhesives and low-emission resins to further reduce environmental harm. Hotels that choose such materials can showcase their commitment to responsible sourcing, which resonates strongly with eco-conscious travelers.

4.3 Compliance with Green Certifications

Engineered wood products are often available with eco-certifications such as CARB Phase 2 or E0 low-formaldehyde ratings. These certifications help hotels meet international sustainability benchmarks, from LEED to Green Key. By adopting compliant furniture, hoteliers not only support the planet but also enhance their brand reputation in competitive markets.

5. Design Flexibility for Modern Hotel Interiors

Beyond durability and sustainability, hotels increasingly value materials that allow creative freedom in design. Engineered wood meets this need by offering a wide range of finishes, colors, and customization options. Whether a hotel brand seeks minimalist elegance, classic luxury, or contemporary style, engineered wood adapts seamlessly, enabling consistent aesthetics while supporting practical functionality.

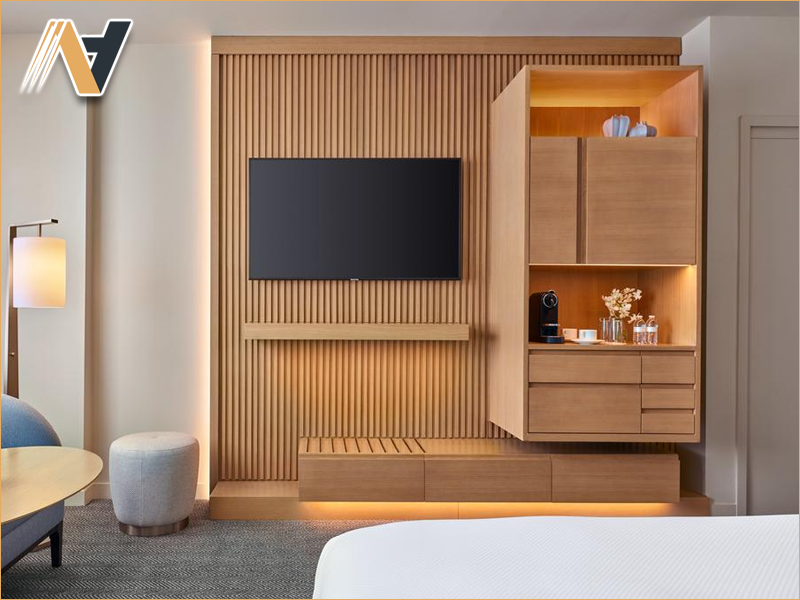

5.1 Wide Range of Finishes

Engineered wood can replicate the appearance of premium hardwoods such as oak, walnut, or teak through veneers and laminates. It can also be finished with high-gloss, matte, or textured coatings to suit different atmospheres. This versatility allows hotels to achieve luxurious visual effects without the expense and limitations of natural timber.

5.2 Customization Opportunities

Because engineered panels are easy to cut, shape, and finish, they allow for bespoke furniture design that aligns with each hotel’s branding. From headboards with unique patterns to reception desks tailored for specific layouts, customization is straightforward and cost-effective. This adaptability ensures that even chain hotels can differentiate properties while maintaining cohesive brand identity.

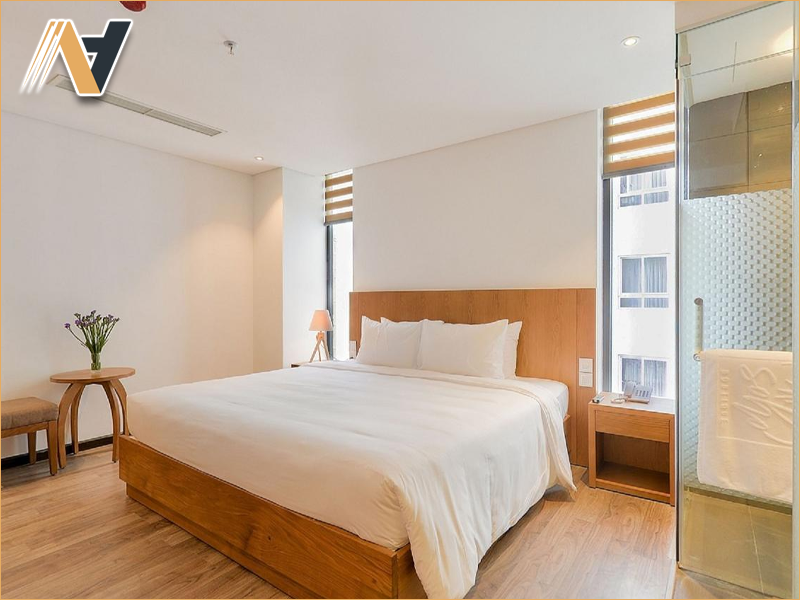

5.3 Adaptability Across Hotel Segments

Engineered wood is equally effective in budget hotels, boutique properties, and five-star resorts. Its ability to balance cost and design flexibility makes it a universal solution. Hoteliers can adjust material choices according to target markets using simple laminates for budget-friendly rooms or premium veneers for luxury suites without sacrificing consistency in overall design quality.

6. Conclusion

Engineered wood furniture has become increasingly popular in hotels thanks to its cost efficiency, durability, sustainability, and design versatility. By combining practicality with style, it provides the ideal solution for modern hospitality interiors. For projects seeking high-quality production in line with these trends, Vietnam hotel furniture OEM by Ngoc Hoang Anh delivers professional solutions tailored to every hotel’s needs.

Contact us today for expert consultation and premium manufacturing support for your hospitality project.

-----

NGOC HOANG ANH TRADING COMPANY LIMITED

Tax Code: 3702874413

Address: No. 288/28/10 Huynh Van Luy Street, Zone 7, Phu Loi Ward, Ho Chi Minh City, Vietnam

Warehouse: No. 1/91, Thuan Giao 02 Street, Binh Thuan 2 Residential Quarter, Thuan Giao Ward, Ho Chi Minh City, Vietnam

Phone/Whatsapp/Wechat: +84342076666

Email: info@ngochoanganh.com.vn